By Loz

Blain

February 26, 2021

Facebook

Twitter

Flipboard

LinkedIn

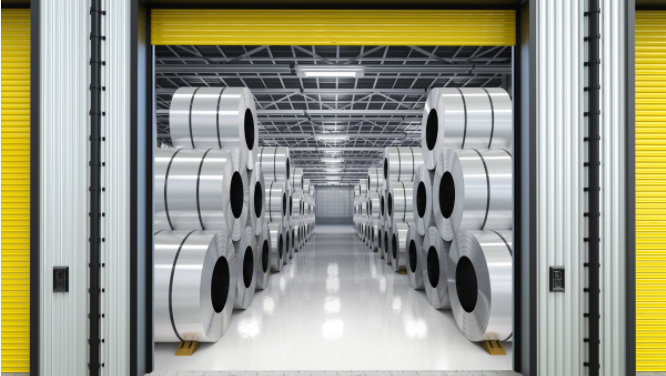

Steel

production is responsible for about 8 percent of global carbon emissions

annually, but hydrogen-based production offers an opportunity to make the

process completely emissions-free Photo:

phonlamai/Depositphotos

VIEW 1 IMAGES

In typical production, blast or

electric arc furnaces combine iron ore and limestone with coke (coal that's been

baked at high temperatures to remove impurities) to create steel. But that coke

reductant can be replaced with hydrogen, resulting in a process that emits

nothing but water, and hydrogen can also be used to power the arc furnaces,

giving you a steel production pipeline that's totally emissions-free.

Every major steel producer in the

world is considering something similar to bring its emissions down, and there

are plenty of incentives for downstream customers like automakers to get on

board with green steel as it becomes available. A new development in Northern

Sweden, headed up by the current CEO of Scania, aims to get some volume into the

market early.

H2 Green Steel (H2GS) is working

with a budget of around US$3 billion dollars. It will use hydrogen produced with

renewable energy from Sweden's Boden-Luleå region, and production is scheduled

to begin in 2024. By 2030, H2GS expects to be producing five million tons of

high-quality zero-emissions steel annually.

The company says it'll be the

first large-scale fossil-free steel plant, producing hot rolled, cold rolled and

galvanized coils, which it expects to sell into the automotive, transportation,

construction, pipeline and whitegoods markets, among others.

“We want to accelerate the

transformation of the European steel industry," says Carl-Erik Lagercrantz,

Chairman of the H2GS board, in a press release. "Electrification was the first

step in reducing carbon dioxide emissions from the transportation industry. The

next step is to build vehicles from high-quality fossil-free steel.”

This project is another

encouraging indication of the increased appetite major investors are showing for

decarbonization initiatives, which typically involve more risk and a longer wait

for a return on investment than other places they could put their money.

But like all hydrogen-based

initiatives, the H2GS project is going to need the price of green hydrogen to

come down dramatically to realize its full potential. The vast majority of

hydrogen produced today is grey, or dirty, often involving the use of fossil

fuels such as natural gas or coal.

Source: H2

Green Steel